multicut sheet

04.11.2025

Imaging Solutions proves its expertise in digital print finishing

Imaging Solutions AG (ISAG), based in Switzerland, is a leading provider of innovative industrial equipment for the production of high-quality print products. The company's portfolio includes finishing solutions such as new cutting/sorting machines (fastCut for photos; wideCut for book pages, calendars, and posters; multiCut for mixed formats), packaging equipment, layflat photo book machines, and canvas stretching machines.

Restructuring

ISAG's origins lie in the manufacture of equipment for processing silver halide paper. In 2024, this was spun off into a new, independent company: GretagX, which operates from Issum in Germany. This restructuring enables Imaging Solutions AG to focus more strongly on its core competencies in the field of post-processing equipment.

As the market for digital printers continues to grow and capture a significant share of the graphics and photo market, ISAG has recognized the importance of increased cooperation with manufacturers of digital printing systems. By spinning off its silver halide printer activities into GretagX GmbH, the company aims to reduce competitive conflicts and get involved in new developments in the digital printing industry at an early stage.

Product innovation

Category

Product Innovation

Client

Inhouse

The new multiCut Sheet

High-quality print processing

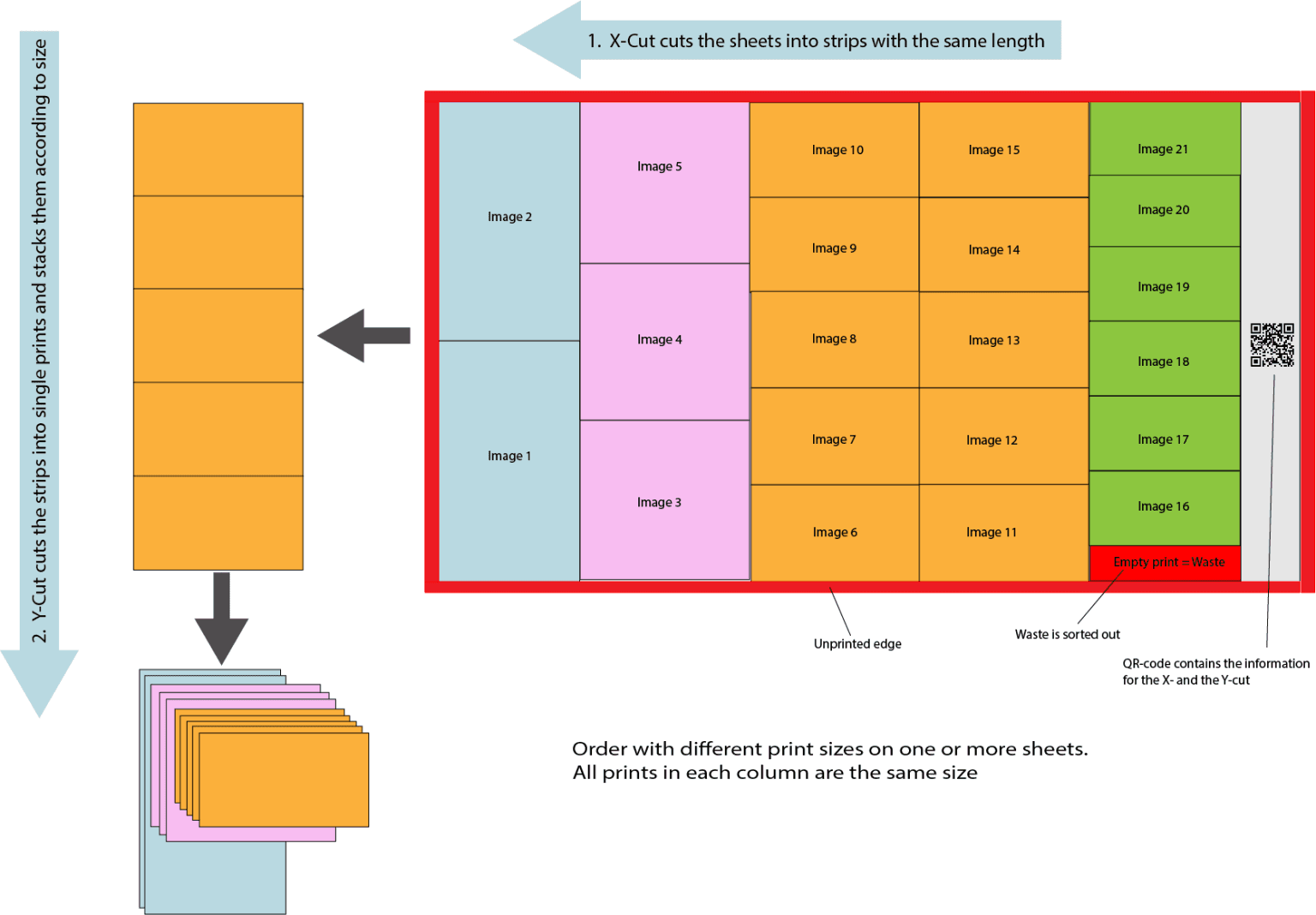

Processing multi-format jobs is a major challenge for print shops and photo labs, as it requires a lot of space and personnel to sort and store all formats of a job before they are merged and packaged. However, there is a solution that reduces this effort and significantly simplifies the production process—without splitting the print jobs during processing.

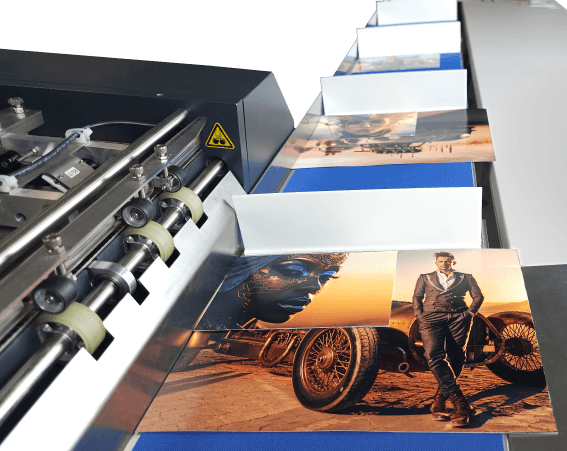

The new XY-Cutter multiCut Sheet is the perfect solution for multi-format jobs printed on variable formats such as B2+ and SRA3+ sheets. It cuts and sorts these images into jobs ready for shipping.

Unlike other cutting machines, the multiCut Sheet can process different image sizes mixed on a single printed sheet. This reduces the considerable sorting and storage effort required before merging and packaging, which is typically necessary with other cutting machines when processing multi-format jobs.

How the multiCut Sheet works in practice

The arrangement of images of different formats in a job begins with the largest format and ends with the smallest. This simplifies removal for packaging after processing.

The multiCut Sheet feeder accepts sheet widths from 320 to 585 mm, and sheet lengths from 450 to 750 mm. The cutting capacity is up to 11'000 images in 10 x 15 cm format per hour. Paper thicknesses from 0.2 to 0.3 mm can be processed.

First, roller knives cut off the unprinted edges and shred them into small pieces. Then, the X-cut divides the sheets into strips with images of equal size, which are then cut out of the strip by the subsequent Y-cut.

An inkjet printing unit is available as an option, which can print customer-specific information on the back of each individual image.

Contact:

Imaging Solutions

www.isag.com